Pipe and Tank

Composite ductwork has been used in chemical manufacturing plants for more than 25 years. During the 1970s, the use of composites in industrial applications became widespread. Today, composite pipe, duct and tank installations are on the rise – above and below ground, in commercial, municipal and residential applications. Low-cost natural gas is further expanding the market with the development of new chemical facilities and the expansion of older ones for chemical processing.

Properties and Benefits

- Corrosion resistant

- Durability

- High strength-to-weight ratio

- Design flexibility

- Elevated temperature service

- Thermal cycling

- Dimensional stability

- High dielectric strength

- Ability to consolidate parts

- Longer lifespans

Applications and Products

- Air Pollution Control

- Aquaculture

- Chemical Processing

- Desalination

- Oil & Gas

- Water and Wastewater Treatment

- Pipes

- Pipe fittings and liners

- Ductwork

- Tank liners

- Storage tanks

- Process vessels

- Scrubbers

- Valves

Case Studies

Fish Friendly Power Plant

FiberSystems in Dayton, Ohio, made a splash when its composite pipe was chosen over conventional materials for a fish-friendly project at National Grid’s Port Jefferson Power Station on Long Island.

GE Thermoplastic Pipe

In 2016, GE Oil & Gas introduced its “next-generation Wellstream flexible risers” – made with carbon fiber thermoplastic composites to lower cost, improve reliability and reduce downtime of offshore operations.

Resins for Tanks

From stack linings in coal-fired power plants to large tanks for chlorine bleach storage, composite applications can withstand some very harsh industrial settings. The reason these structures are so tough? Their resins.

World Trade Center

Owens Corning’s fiberglass piping products were specified in several WTC sites, including One World Trade Center, the World Trade Center Transportation Hub and the National September 11 Memorial.

Bronx Water Filtration Plant

A new water filtration plant in The Bronx is the centerpiece of the largest single construction project in the history of New York City. Learn More

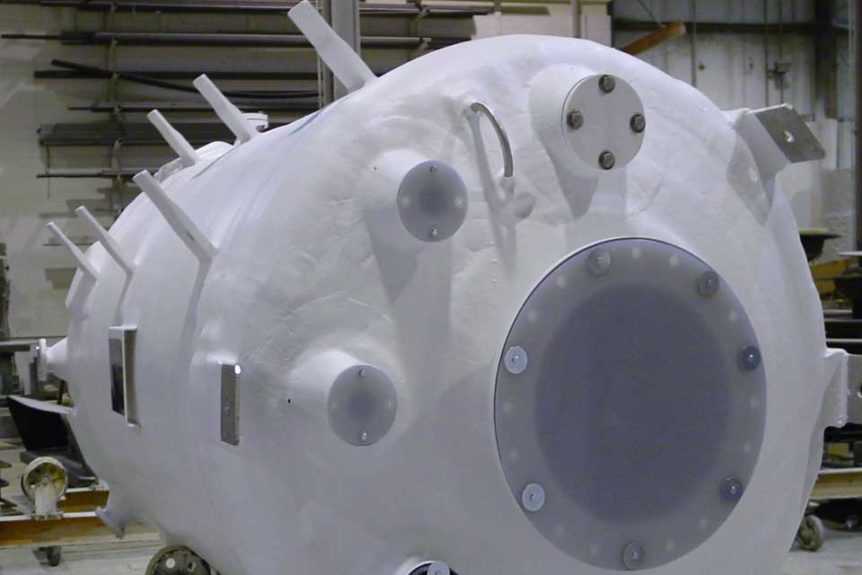

Bleach Tank

Composite tanks are a cost-effective choice for the storage of sodium hypochlorite (bleach). In 2015, Design Tanks LLC fabricated a 7,000-gallon bleach tank for the City of Helena, Mont. Learn More

Bleach Storage Trends

The movement away from bulk chlorine rail shipments is causing an upsurge in the regional production distribution and storage of concentrated sodium hypochlorite. Learn More

Cooling Water Pipe

In 2012, a large independent energy producer contracted RPS Composites to supply approximately 3,000 feet of large diameter FRP cooling water pipe and associated fittings for a project in the Caribbean. Learn More

Intel Corporation Ducting

In the 1980s, Intel Corporation was adding chip capacity at a rapid pace, which meant they needed to look at corrosion resistant ducting to vent the waste air stream from their etching operations. Learn More

Acid Cover Repair

RPS Composites regularly works with AK Steel, a steel manufacturer in Ohio, to repair pickle line covers on a continual preventive maintenance basis. Learn More

Copper, Cobalt, & Zinc Processing

This large-scale project to engineer, design, supply and install a settler and storage tank lining system featured 15,000 square meters of FRP panels. Learn More

Caustic Line Replacement

For over two years, RPS Composites worked with an international customer to provide an alternative to using carbon steel pipe for a caustic line replacement. Learn More

Liquid Fertilizer Tanks

Many agricultural companies are switching from mild steel storage tanks to fiberglass due to the more corrosive nature of fertilizer blends. Learn More

Chlorine Dioxide Tanks

In 1994, Fabricated Plastics manufactured two huge chlorine dioxide tanks for a pulp mill in Ontario, Canada. Due to the size of the tanks, they were shipped in sections. Learn More